Gridiron pendulum

The gridiron pendulum was a temperature-compensated clock pendulum invented by British clockmaker John Harrison around 1726.[1][2][3][4] It was used in precision clocks. In ordinary clock pendulums, the pendulum rod expands and contracts with changes in temperature. The period of the pendulum's swing depends on its length, so a pendulum clock's rate varied with changes in ambient temperature, causing inaccurate timekeeping. The gridiron pendulum consists of alternating parallel rods of two metals with different thermal expansion coefficients, such as steel and brass. The rods are connected by a frame in such a way that their different thermal expansions (or contractions) compensate for each other, so that the overall length of the pendulum, and thus its period, stays constant with temperature.

The gridiron pendulum was used during the Industrial Revolution period in pendulum clocks, particularly precision regulator clocks[1] employed as time standards in factories, laboratories, office buildings, railroad stations and post offices to schedule work and set other clocks. The gridiron became so associated with accurate timekeeping that by the turn of the 20th century many clocks had pendulums with decorative fake gridirons, which had no temperature compensating qualities.[1]

How it works[edit]

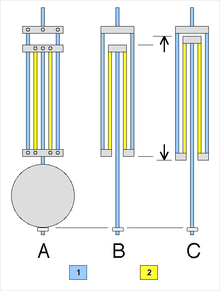

B: normal temperature

C: higher temperature

The principle of the gridiron pendulum is that it is constructed so the high expansion (zinc or brass) rods make the pendulum shorter when they expand, while the low expansion steel rods make the pendulum longer. By using the correct ratio of lengths, the greater expansion of the zinc or brass rods exactly compensate for the greater length of the low expansion steel rods, and the pendulum stays the same length with temperature changes.[2]

The simplest form of gridiron pendulum, using steel and zinc rods, consists of five rods. A central steel rod runs up from the bob to a point immediately below the suspension.

At that point a cross-piece (middle bridge) extends from the central rod and connects to two zinc rods, one on each side of the central rod, which reach down to, and are fixed to, the bottom bridge just above the bob. The bottom bridge clears the central rod and connects to two further steel rods which run back up to the top bridge attached to the suspension. As the steel rods expand in heat, the bottom bridge drops relative to the suspension, and the bob drops relative to the middle bridge. However, the middle bridge rises relative to the bottom one because the greater expansion of the zinc rods pushes the middle bridge, and therefore the bob, upward to match the combined drop caused by the expanding steel.

In simple terms, the upward expansion of the zinc counteracts the combined downward expansion of the steel (which has a greater total length). The rod lengths are calculated so that the effective length of the zinc rods multiplied by zinc's thermal expansion coefficient equals the effective length of the steel rods multiplied by iron's expansion coefficient, thereby keeping the pendulum the same length.

Harrison's original construction using brass (pure zinc not being available then) is more complex because brass does not expand as much as zinc does. A further set of rods and bridges is needed giving nine rods in all, five steel and four brass. The exact degree of compensation can be adjusted by having a section of the central rod which is partly brass and partly steel. These overlap (like a sandwich) and are joined by a pin which passes through both metals. A number of holes for the pin are made in both parts and moving the pin up or down the rod changes how much of the combined rod is brass and how much is steel. In the late 19th century the Dent company marketed a further development of the zinc gridiron in which the four outer rods were replaced by two concentric tubes which were linked by a tubular nut which could be screwed up and down to alter the degree of compensation.

Disadvantages[edit]

Scientists in the 1800s found that the gridiron pendulum had disadvantages that made it unsuitable for the highest-precision clocks[4]. The friction of the rods sliding in the holes in the frame caused the rods to adjust to temperature changes in a series of tiny jumps, rather than with a smooth motion. This caused the rate of the pendulum, and therefore the clock, to change suddenly with each jump. Later it was found that zinc is not very stable dimensionally; it is subject to creep. Therefore, another type of temperature-compensated pendulum, the mercury pendulum, was used in the highest-precision clocks.

By 1900, the highest-precision astronomical regulator clocks used pendulum rods of low thermal expansion materials such as invar and fused quartz.

Gallery[edit]

References[edit]

- ^ a b c Turner, Anthony; Nye, James; Betts, Jonathan (2022). A General History of Horology. Oxford University Press. p. 321. ISBN 9780192609366.

- ^ a b Baker, Gregory L. (2011). Seven Tales of the Pendulum. Oxford University Press. pp. 79–82. ISBN 9780191004841.

- ^ "Clock". Encyclopaedia Britannica, 11th Ed. Vol. 6. The Encyclopaedia Brittanica Co. 1910. p. 539. Retrieved 7 July 2024.

- ^ a b Matthys, Robert J. (2004). Accurate Clock Pendulums. OUP Oxford. pp. 8–10. ISBN 9780198529712.

Further reading[edit]

Reid, Thomas (1826). Treatise on Clock and Watch Making. Edinburgh: James Clarke and Co. pp. 363–371. Beckett, Edmund (Lord Grimsthorpe) (1874). A Rudimentary Treatise on Clocks and Watches and Bells, 6th Ed. London: Lockwood & Co. p. 50-60.